Lifting the lid on Chesterfield's rich legacy of pottery-makers

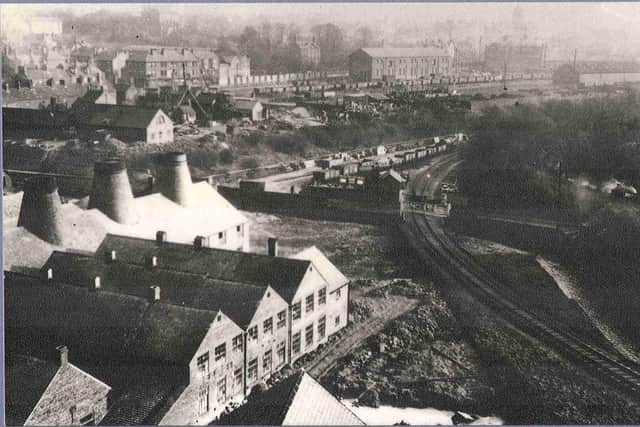

The biggest concentration of businesses was in the Brampton area where ten potteries were within walking distance of Old Road.

By the mid 19th century there were at least 16 potteries in Brampton, Whittington and Newbold.

Advertisement

Hide AdAdvertisement

Hide AdWirksworth potter Josie Walter, who researched the industry for a touring exhibition, shared the following findings in a booklet which she published for the project while studying for an MA in the history of ceramics.

The saltglaze stoneware that emerged from Chesterfield potteries were fired once in kilns that were heated to a high temperature. Salt was shovelled into the kilns which vaporised and the vapour reacted with chemicals in the clay body of the pot to form a hard, shiny surface. This process was particularly useful in making bottles at a time when glass was too expensive for everyday use.

Many of the pottery owners also owned collieries and would extract the refractory clays needed for salt glazing as well as having a readily available supply of coal to fire the kilns.

Brampton ware included ornate sprig decorated pottery comprising jugs, toast racks, teapots and coffee pots, made from an almost white clay that was given a honey colour during salt firing.

Advertisement

Hide AdAdvertisement

Hide AdStew and sauce pots, turtle and beef pots, pudding moulds and water filters in a darker brown were also produced at the Brampton potteries.

When coal-fired cooking ranges became all the rage the potteries made bread bakers and pots with feet on them to stop the bases touching the bottom of the very hot ovens so that the contents didn’t burn.

In the second half of the 19th century the Brampton potteries began making round or oval shaped dishes, known as nappers, which were suitable for baking puddings quickly in the cooking ranges, rather than having to boil them for hours.

Cold puddings, ice cream and jelly became fashionable in the 19th century and Pearson’s Pottery started making jelly moulds in stoneware.

Advertisement

Hide AdAdvertisement

Hide AdIn the 1870s the abolition of the duty on sugar encouraged the nation’s sweet tooth and jam production went into high gear, the preserve being used to mask the taste of margarine. The Midland Preserving Company was based close to Whittington Moor potteries and Pearsons Pottery produced thousands of jam pots and marmalade jars every year.

Chesterfield’s good transport links via the canal, the North Midland Railway which launched in 1840, and roads to Derby, Birmingham, Sheffield, Leeds, Manchester and Livepool helped to increase the market potential of pottery produced in the town.

Pottery workers were a forceful, powerful bunch, according to Bolehill-based Josie who researched her topic in Chesterfield and Erewash museums among other places. The workers would meet every month in the Star Inn, Brampton, and collaborate in the buying of material in bulk, standardise the size of pots, agree the price and fix the rates of pay.

Supplying additional information about the Brampton potteries, Chris Townsend highlighted an article from the Derbyshire Times in 1888 when there was a walkout against a pay cut. Several of the men at Goslings Potteries had been on strike for a week and were determined to hold out against a ten percent reduction in their wages.

Advertisement

Hide AdAdvertisement

Hide AdIn another press cutting in 1898, the Derbyshire Times reported a fire at the pottery in Beehive Yard. A fire had been lit in a kiln, and contrary to orders, the burner had left the premises to go home for his supper. During the worker’s absence, the kiln overheated and the resulting blaze caused the roof and second floor hall to drop in; all the remained were two kilns and walls of the chamber.

Chris says that the the fire-stricken pottery’s yard may have been on land that is now known as Beehive Road while the business may also have used the site now occupied by Serpent Motors. The pottery closed in 1905 and the building of the Gospel Mission Church on Beehive Yard began later that year.

In 2008 Chris launched the Potteries Festival to honour the traditional industry in Brampton by encouraging the residents of Old Road to decorate flower pots in innovative way and showcase their creations in gardens. The last event was held in 2019 but its organiser hasn’t ruled out the festival coming back. Chris said: “I think if local residents, schools and businesses are willing to give it their support once again it might well happen.”

Janine Mannion-Jones is flying the flag for Brampton’s traditional industry. She launched JMJ Pottery 20 years ago after converting a former aquatics shop on Chatsworth Road into her pottery business, self-contained holiday accommodation and a shop to let.

Advertisement

Hide AdAdvertisement

Hide AdJanine said: “I decided that I needed a shop window and workshop behind where the stoneware pottery is made, continuing the tradition of the Brampton pottery industry.”

Prior to launching her business on Chatsworth Road, Janine created her pottery in the Corner Workshop for five years.

Her interest in clay pottery was fuelled at Saturday morning art classes, tutored by Chris Yenson, at the Penmore site of Chesterfield College in 1964. Janine said: “Once smitten I have continued over the years and in 1995 resigned from my teaching job to start another career. Twenty-five years later, no regrets, I enjoy coming to work every day, tutoring and making bespoke pottery to order.”

Advertisement

Hide AdAdvertisement

Hide AdSupport your Derbyshire Times by becoming a digital subscriber. You will see 70 per cent fewer ads on stories, meaning faster load times and an overall enhanced user experience. Click here to subscribe.